| Introduction of Hysteresis Brake and Its Profile Technical Parameters |

| Hits:31630 AddTime:2023/9/20 9:05:16 |

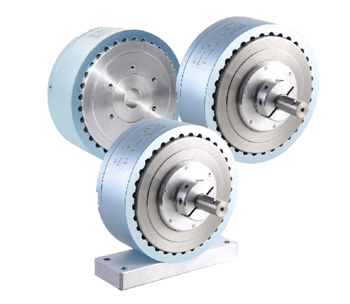

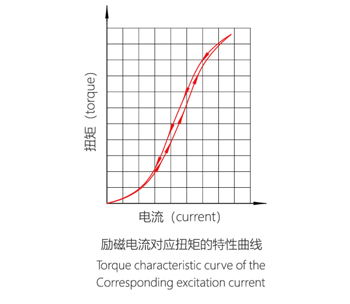

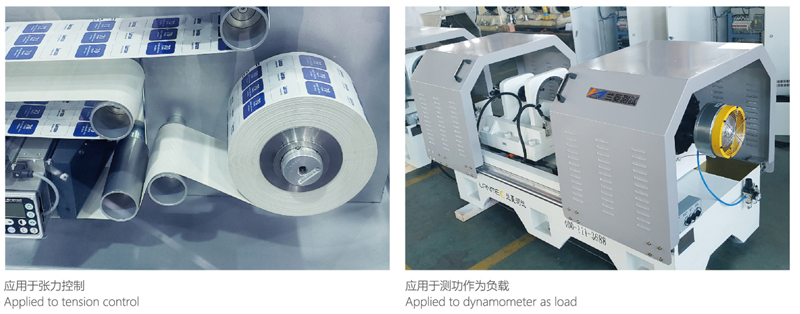

Overview Hysteresis brake is a superior torque and tension control component. It uses hysteresis principle to generate a certain amount of torque by controlling the input excitation current. There is a good linear relationship between control current and outpu torque. It provides smooth,steplessly adjustable,torque control unrelated with speed. In addition to the bearings, there is no other friction in the system, which has the advatages of stable and reliable,high speed of use, low noist, long service lift and low maintenance cost.

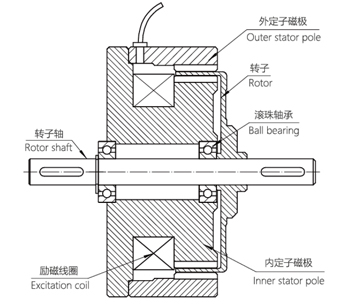

Hysteresis brake consists of two parts, the roor and the stator pole. The rotor is made of a special hysteresis material, stator pole has a certain qap, rotor rotates in the qap. When the coil is energized, magnetic field is generated in the gap, causing a hysteresis effect on thel rotor. When the hysteresis rotor rotates against the hysteresis force under the action of an external force, torque is g enerated. Torque is oniy related to the excitation current, irrelevant with speed can achieve non-contact torque transfer.

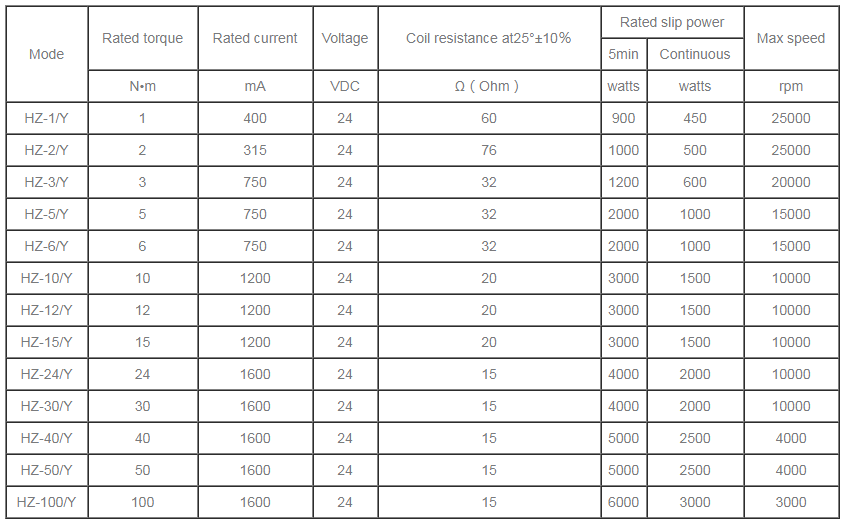

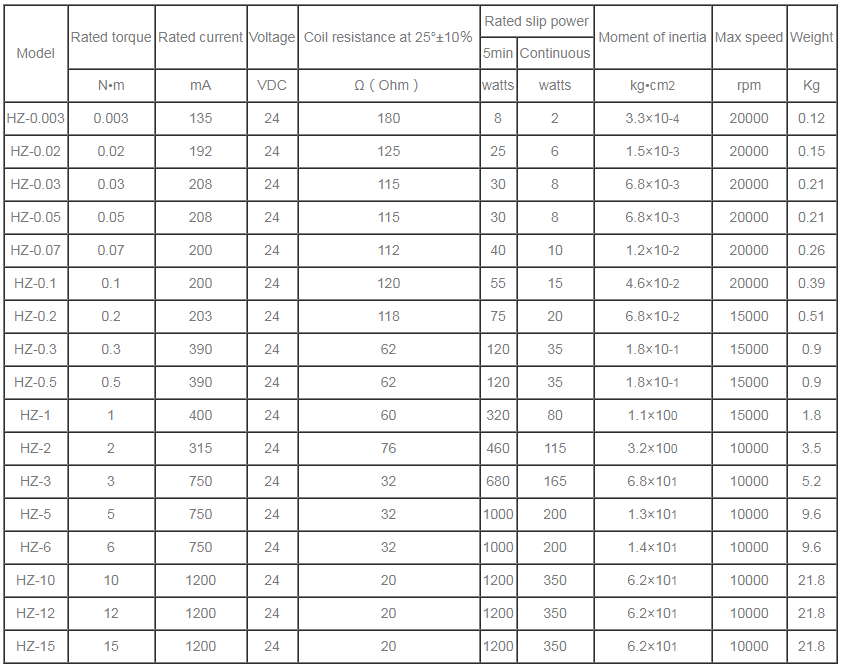

Excitation current is basically linear with the output torque,which can be controlled within 5-100% of the rated value.Large ou Calculation method In the case of winding processing,tension control is often required. The actual tension on the wire and strip at this time is determined by the following formula. F=M÷R F─tension N(Newton) R─material roll radius m(m) M─torqueN•m(N•m) During the operation of hysteresis brake, the power consumed is converted into heat . If the rated slip power is exceeded , the device will be damaged by overheating. Slip power P=M×n÷9.55=F×v

P─slip power w(Watt) n─slip speed rpm(r/min) M─transfer torque N•m(N•m) F─tension N(NEWTON) V─line speed m/s(m/s)

One of the most important issues to be aware of when using a hysteresis brake is the residual torque wave. The residual torque wave is that when the excitation current is turened off, the alternating magnetic pole of the N pole remains inside ,and the residual wave-shaped torque deviation phenomenon occurs when the rotation continues . If the excitation current is disconnected without rotation, a residual torque of 5 to 10% of the torque value before the excitation current is turned off occus ,and the characteristic is a jitter phenomenon (pulsation) that generates one hop and one hop during rotation. When restarting, if the excitation current of 60~70% or more bdefore the disconnection is restarted ,the residual torque wave will not occur. For example ,if the current is 250 mA before disconnection and 150 mA when restarting, no residual torque will be generated, and when the current is less than 150 mA,such as 100 mA,residual torque will be generated. The method to eliminate and prevent residual torque waves is as follows; 1. Usuallly used When the rotation speed is 50 r/min or more,the residual torque wave hardly occurs when the excitation current is turned off . However, some models has different current breaking speeds,sometimes leave a little residual torque. At this time,it is mecessary to further increase the rotational speed. 2.When the rotation speed is 50 r/min(5 seconds) 5r/min or less(20 seconds or more) if the excitation current is slowly turned off in accordance with the above time,residual torque does not occur. 3.Apply a current opposite to the direction of the excitation current When there is a residual torque wave,reverse the postitive and negative poles of the excitation coil, apply 30 to 50% of the current before the current is turned off for a short time. However ,if the input rotor and the output rotor are independent of each other,there is no effect due to the devation of the magnetic poles, and it is necessary to maintain there is no relative rotation of the stator and the rotor in advace. However ,the optimum reverse current value is different depending on the model and the disconnected current value,so although the residual torque wave can be reduced to some extent ,it is still difficult to completely eliminate it.

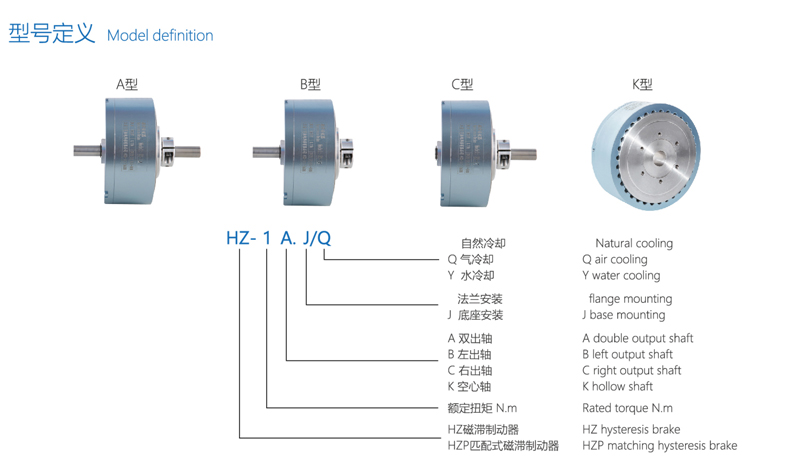

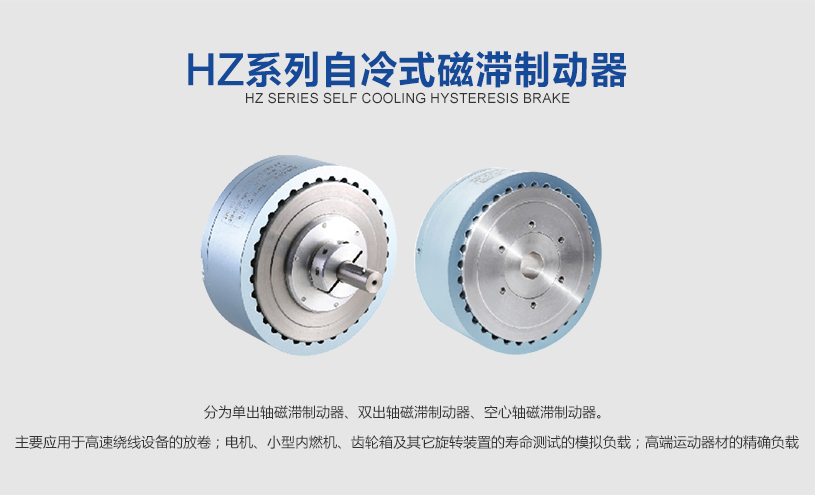

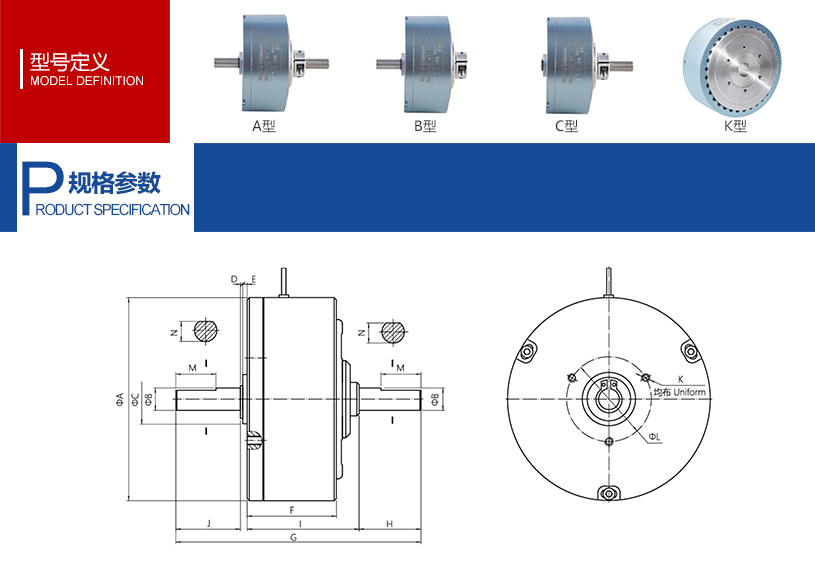

There are three types of self cooling hysteresis brakes single output shaft brakes, double output shaft brakes and hollow shaft hysteresis brakes.

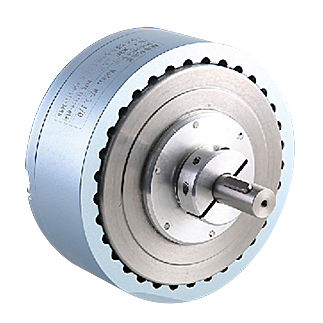

HZ Self cooling hysteresis brake

The design is based on the foundation of self cooling hysteresis brake with add an air cooled device to stator pole.

The torque is very close at a multiple currents specific point ,and multi-shaft tension control can be achieved with only one control system, precision is higher than the normal hysteresis brake.

Based on the self cooling hysteresis brake, water cooling channel is internally provided to absorb heat generated by continuous slip by water cooling . It has the advantages of low noise and high power. Widely used in test loads and high speed large tension unwinding applications.(Please call for specific sizes)

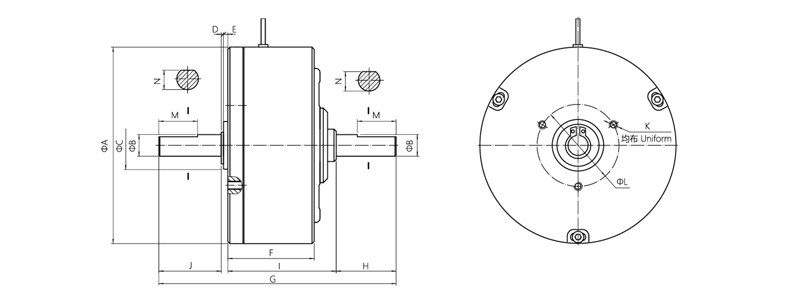

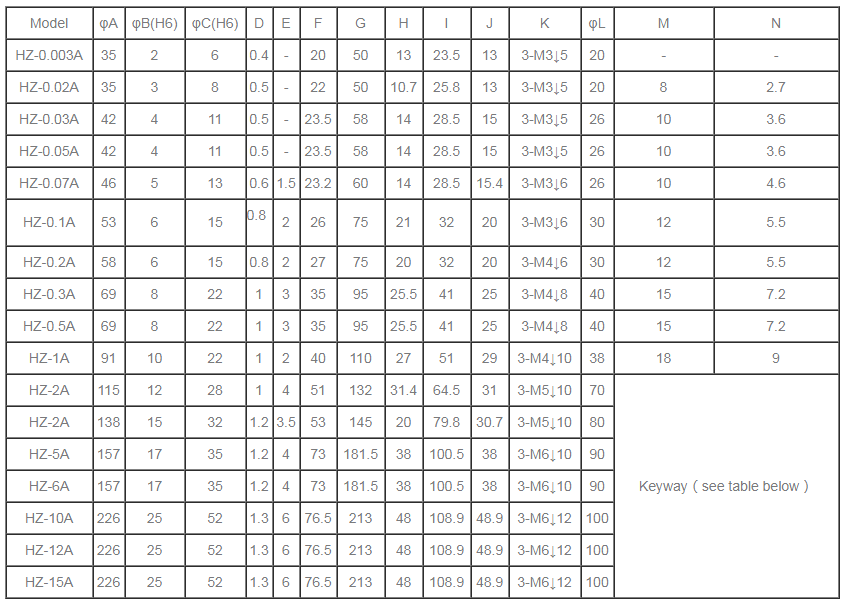

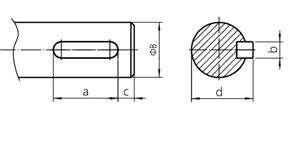

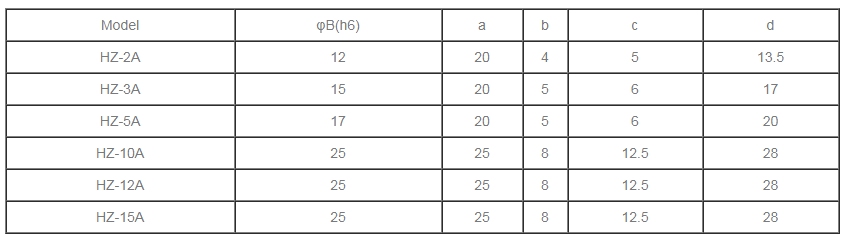

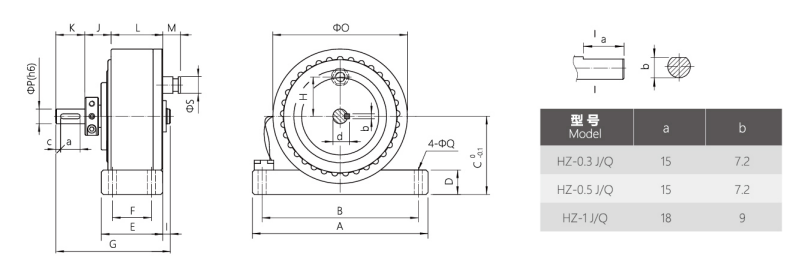

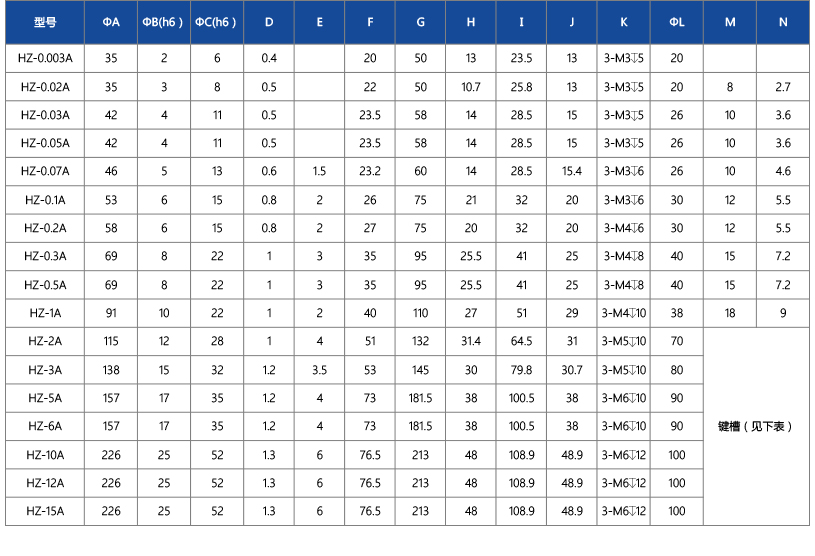

HZ-A Type double output shaft hysteresis brake dimension

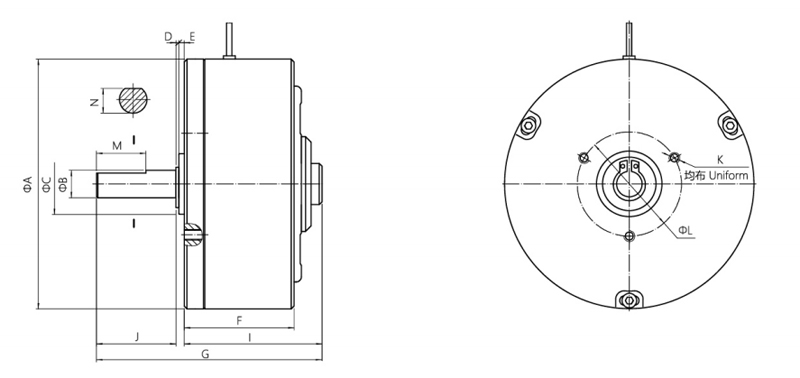

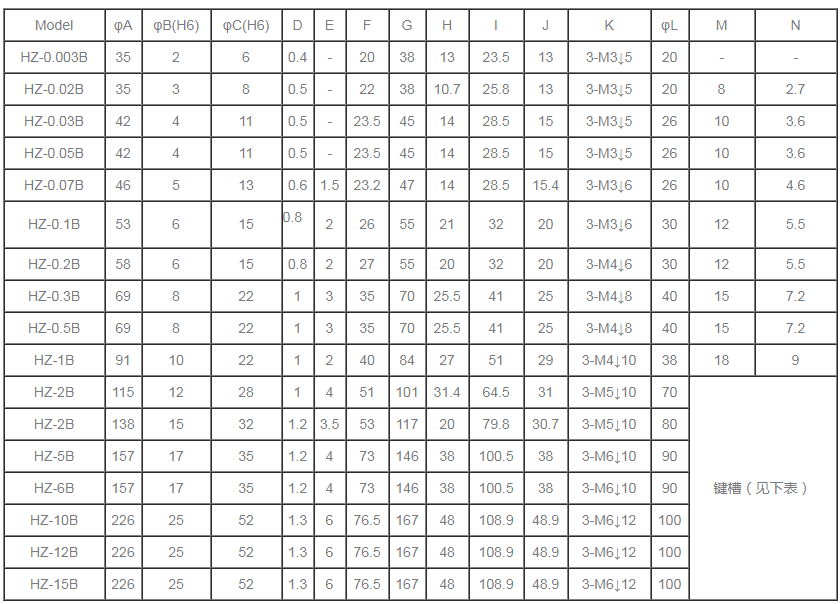

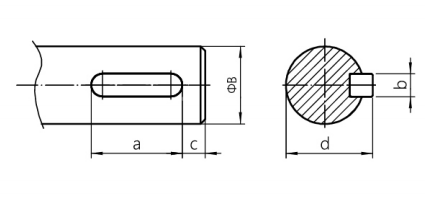

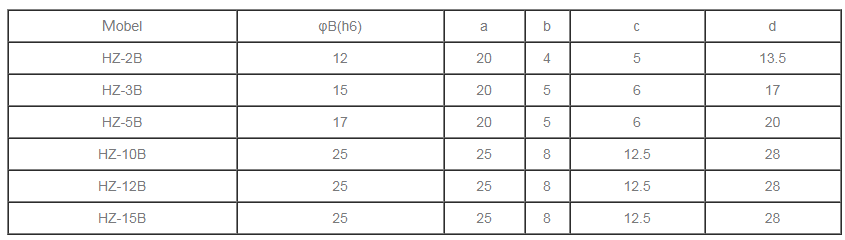

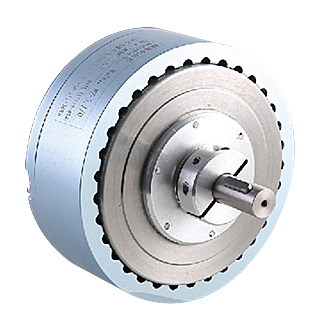

HZ-BType left output shaft hysteresis brake dimension

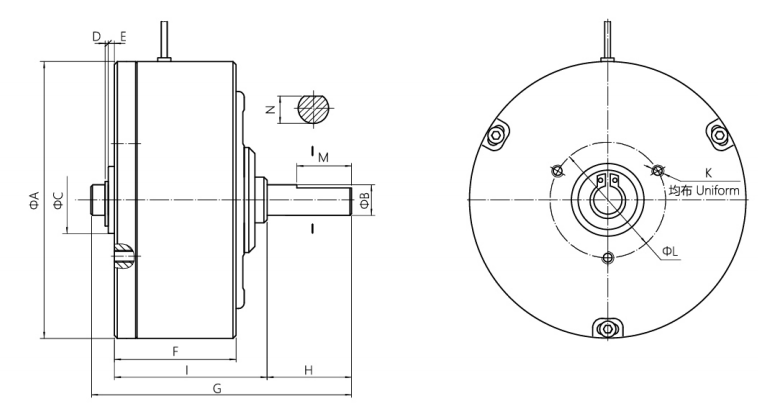

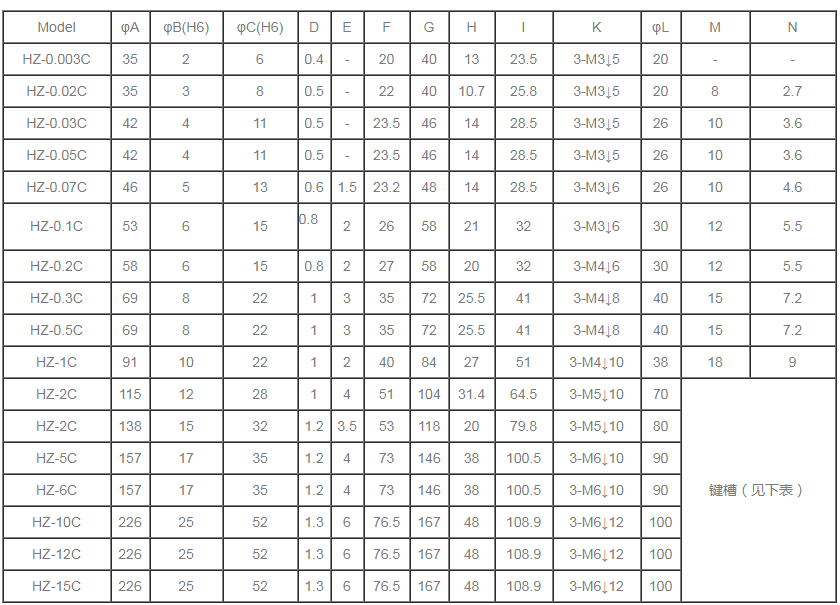

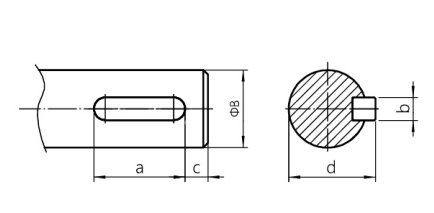

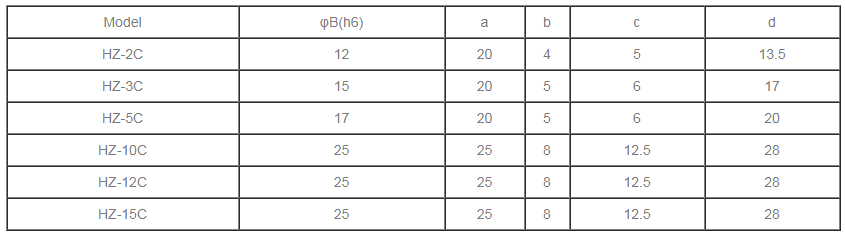

HZ-C Type right output shaft hysteresis brake dimension

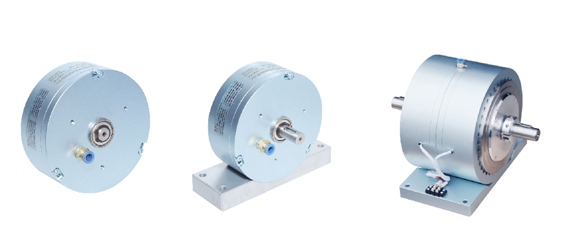

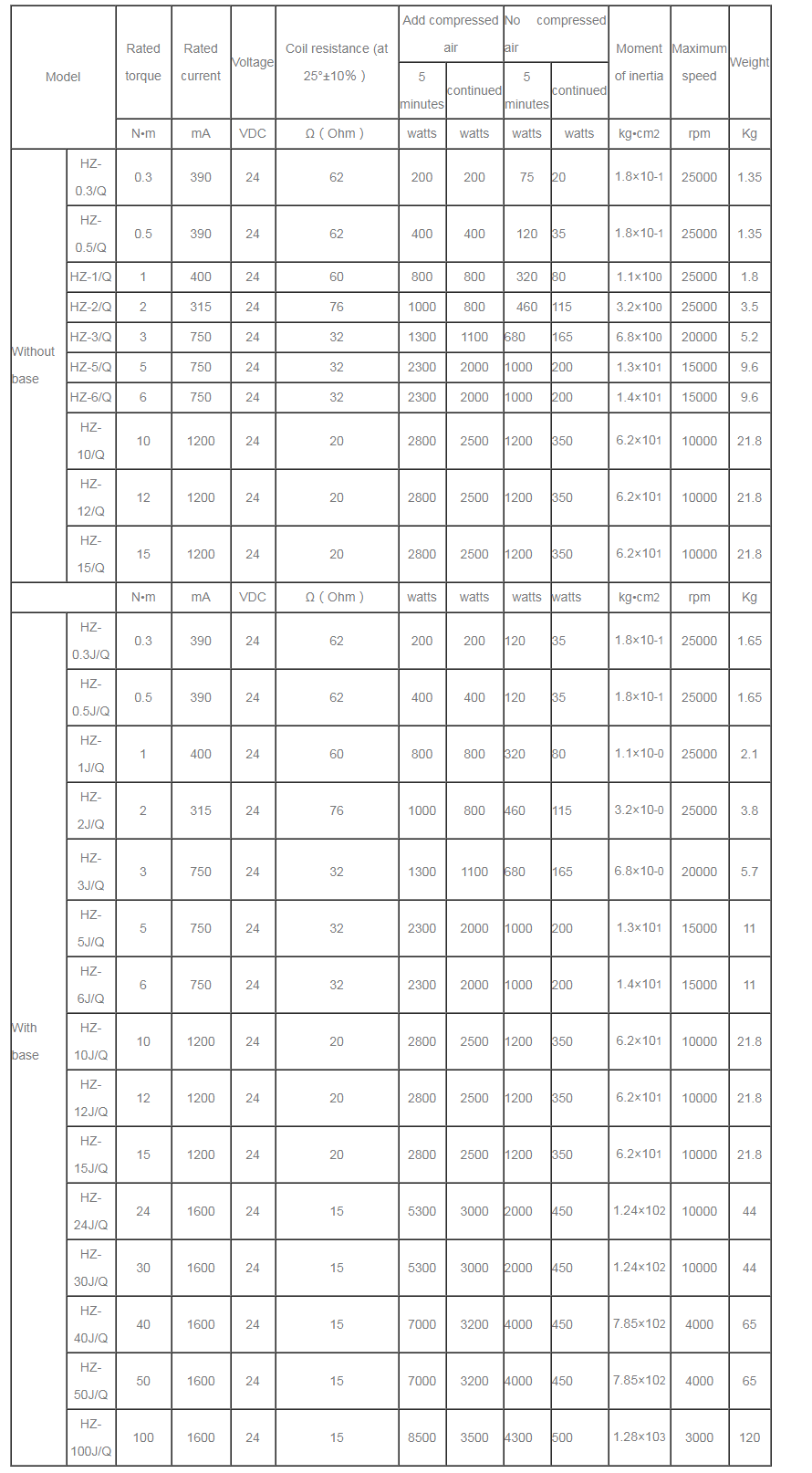

HZ-Q Type air cooling hysteresis brake

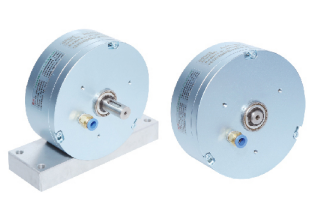

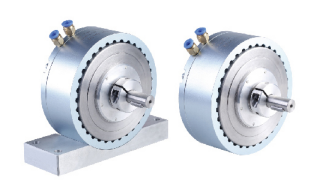

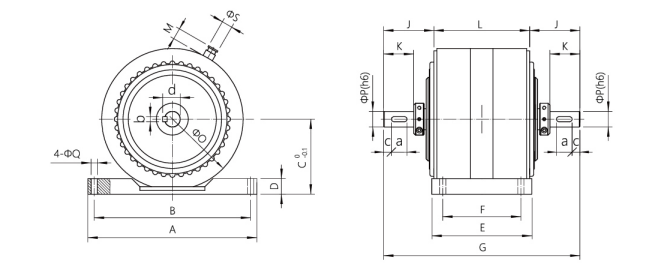

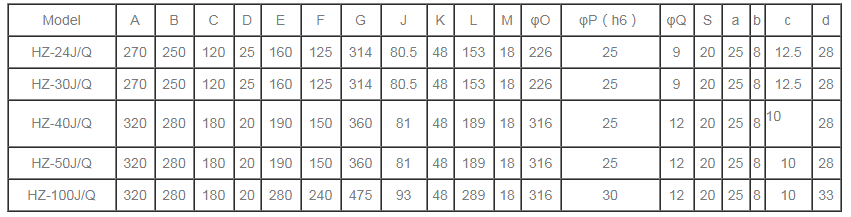

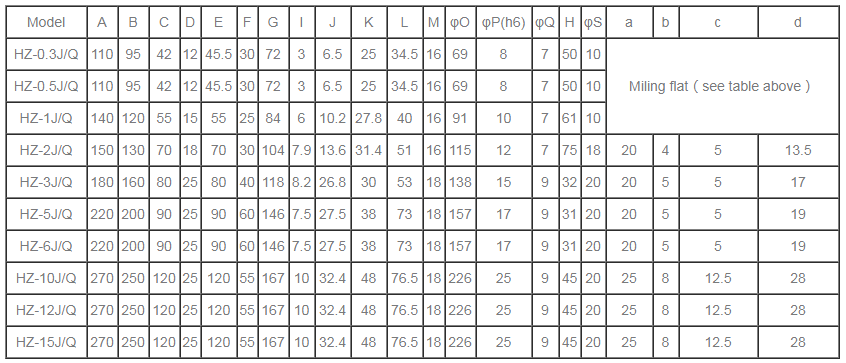

HZ-J/Q Base type air cooling hysteresis brake

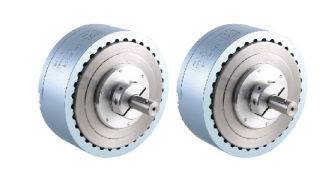

Hz-y double output shaft hysteresis brake

HZ-Y Series water cooling hysteresis brake

Based on the self cooling hysteresis brake, water cooling channel is internally provided to absorb heat generated by continuous slip by water cooling . It has the advantages of low noise and high power. Widely used in test loads and high speed large tension unwinding applications.(Please call for specific sizes)

|

| 【Refresh】【Favorites】【Print】 【Close】 |

| Previous:HZ Series sellf cooling hysteresis brake Next:Axle Test Bench (click to enter) |

- Torque speed sensor

- torque speed sensor

- Magnetic powder clutch

- Magnetic powder brake

- Tension control system

- Deviation control system

- Safety chuck

- Air shaft

- Eddy current brake

- Hysteresis brake

- Hysteresis clutch

- Hysteresis dynamometer

- Eddy current dynamometer

- Electric dynamometer

- Magnetic powder dynamometer

- Hydraulic dynamometer

- Chassis dynamometer

- Drill pipe test bench

- Actuator, worm gear box, test bench

- Engine, axle, gearbox, PTO test bench

- Reducer test bench

- Traction machine test bench

- Motor test bench

- RV, Harmonic and Planetary Test Bench

- Hydraulic pneumatic motor test bench

- Hydraulic wrench test bench

- Testing software

- Slewing bearing test bench

- Acquisition instrument

- New energy vehicle transmission test bench

- Non-standard custom test bench

- High and low temperature test chamber

- coupling

- Industrial chiller